Matching issues between ultrasonic cleaning machines and ultrasonic generators

Strictly speaking, the ultrasonic cleaning industry is not a high-tech industry and does not have much technical content. However, it is not easy to be precise and the best. What I want to talk about here is about the matching of ultrasonic cleaning machines and ultrasonic generators. Please see details below.

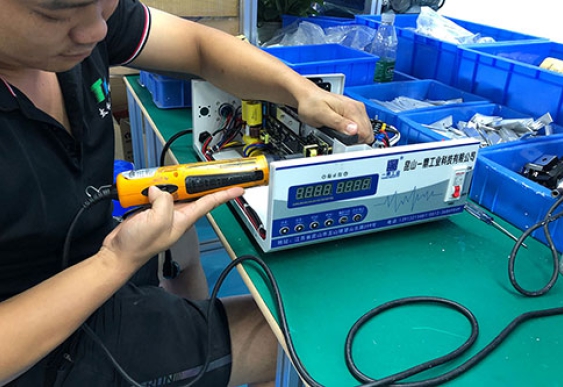

Ultrasonic generators are generally set to 28KHZ when leaving the factory. They are also set to different frequencies such as 23KHZ, 25KHZ, and 40KHZ according to customer needs, which is consistent with the transducer affixed to the customer's ultrasonic cleaning machine. Therefore, after customers purchase the cleaning machine generator, they will connect the wires, plug in the power, and turn on the power switch, and there will generally be ultrasonic output. But the effect is far from reaching the best ultrasonic cleaning effect. Why? Assume that the factory frequency of the purchased ultrasonic generator is 28KHZ, and the power of the transducer installed in the cleaning machine is also 28KHZ. Why can't the output achieve the effect? A very complicated resonance point issue is involved here. In order to complicate the problem, here is a brief description. As mentioned above, they all have a frequency of 28KHZ, but there is no ultrasonic output or the ultrasonic output is very weak, which cannot achieve the best cleaning effect. This is because although each transducer has factory standards, the actual capacitance is different. , the inductance is also different, causing the actual frequency to change after the transducer is pasted. For example, the standard 28KHZ transducer is due to the thickness of the adhesive glue, the verticality of the adhesive screw welding, the tightness of the fixation, and the flatness of the steel plate. Affected by factors such as temperature, the actual frequency of the transducer may become 27.4KHZ, maybe 28.8KHZ, or even more. Fluctuations in the 2KHZ range are normal phenomena. As a result, the average frequency of the entire vibration plate or cleaning machine is not 28KHZ. This requires us to adjust the ultrasonic generator to find the actual frequency of the cleaning machine. The frequency found is the resonance of the ultrasonic cleaning machine and the generator. point. Once you find this resonance point, no matter the ultrasonic current, output, sound, or cleaning effect, it will reach its optimal state. And this process of finding the resonance point is called machine tuning in jargon. Tuning is achieved by changing two aspects. One is to change the inductance of the ultrasonic generator. There are two transformers in the ultrasonic generator, one is the output voltage transformer, and the other is a transformer that changes the inductance. The middle inductance part is separated by several insulating sheets. The adjustment of the inductance is through the Adjusted by changing the thickness of the insulation block. The second is to adjust the frequency. Depending on the digital machine and the meter machine, the adjustment method is also different. For ammeters, you can directly adjust the micropotentiometer W1 with a flat-blade screwdriver and turn it left or right to achieve the best output effect; for digital display machines, adjust it through the panel buttons in the adjustment mode to finally achieve the best output state.

Tiếng Việt

Tiếng Việt English

English